About Us

Clemson Formula SAE competes on an international level through events hosted by the Society of Automotive Engineers (SAE). Each year, we design and build a new vehicle from the ground up that meets the competition rules and pushes for innovation. The Summer and Fall are spent designing the new vehicle, which is then built in the Spring.

The vast majority of our vehicle is produced in-house through various machining and assembly processes. For some of our more complex components, the manufacturing is outsourced to one of our amazing sponsors. The end of the spring semester is spent testing and fine tuning the vehicle in order to prepare for the year’s premier SAE competition: FSAE Michigan.

Our team is broken down into seven divisions that collaborate in a fluid and integration-focused manner to create the finished product. You can read more about each of these divisions and the impact they have on the team as a whole below.

Meet the divisions

Business Division

Formula SAE is about much more than just engineering. Being a part of the Business division provides an unparalleled collegiate experience in all aspects of running a small business. Division members gain valuable experience with recruitment, establishing and maintaining relationships with sponsors, and managing the team’s finances. Members develop their speaking skills through many presentations to alumni, investors, and judges. In addition, a major portion of the Formula SAE competition is a presentation marketing the vehicle to a weekend autocross client.

Members of the business division pose with the Tiger 24 at FSAE Michigan 2024.

Aerodynamics Division

The Aerodynamics division, “aero” for short, is responsible for the components of the car that harness the air around the moving vehicle. The cornerstones of the aero package are the rear wing, front wing, and undertray. Aero division members utilize and gain experience with Computational Fluid Dynamics (CFD) to analyze how their components interact with the air around the car. They also obtain valuable experience with composite manufacturing, using methods such as wet and pre-preg carbon fiber layups and CNC machining.

Aero division members attaching the Tiger 23’s front wing before it runs at FSAE Michigan 2023.

Chassis Division

The Chassis division is responsible for the chassis of the vehicle, as well as the ergonomics and braking subsystems. Members work closely with the other engineering divisions to design a chassis that meets global design goals and provides structural rigidity and mounting for other core components. Division members gain real-world experience with modeling components in SolidWorks, jigging and manufacturing a vehicle chassis, and interdisciplinary technical communication.

Chassis members pose with the completed chassis for the Tiger 23.

electrical Division

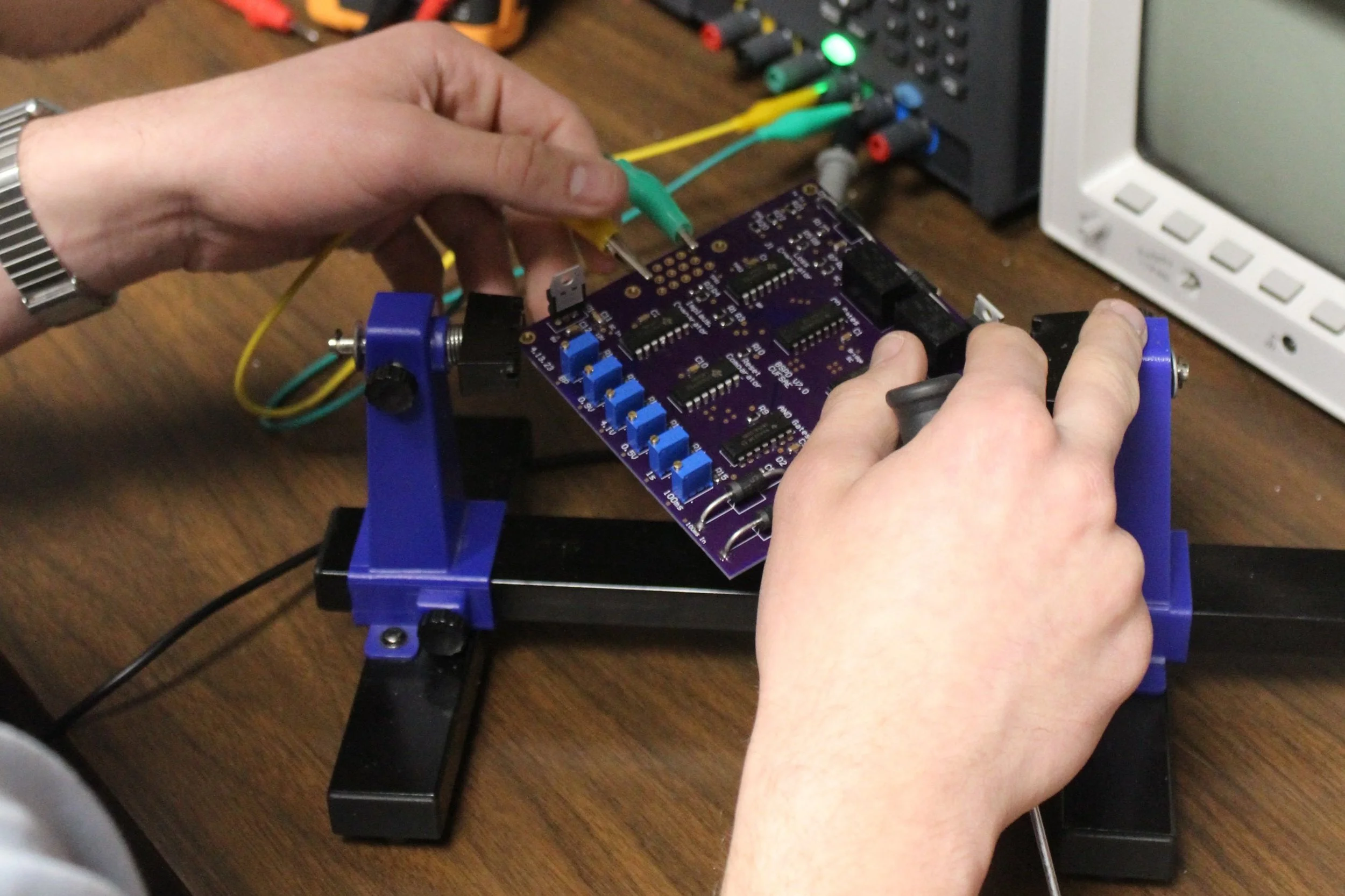

The Electrical division, often referred to as the “subsystem-integration” division, is responsible for the electrical components of the vehicle. The main design task, the wiring harness, is the central nervous system of the vehicle, delivering power and transferring data between key areas of the car. Electrical members gain valuable experience with harness design and manufacturing, PCB design, embedded programming, and pinning and wiring tools and methods.

An Electrical Division member testing a student-designed and custom-built PCB using a power supply.

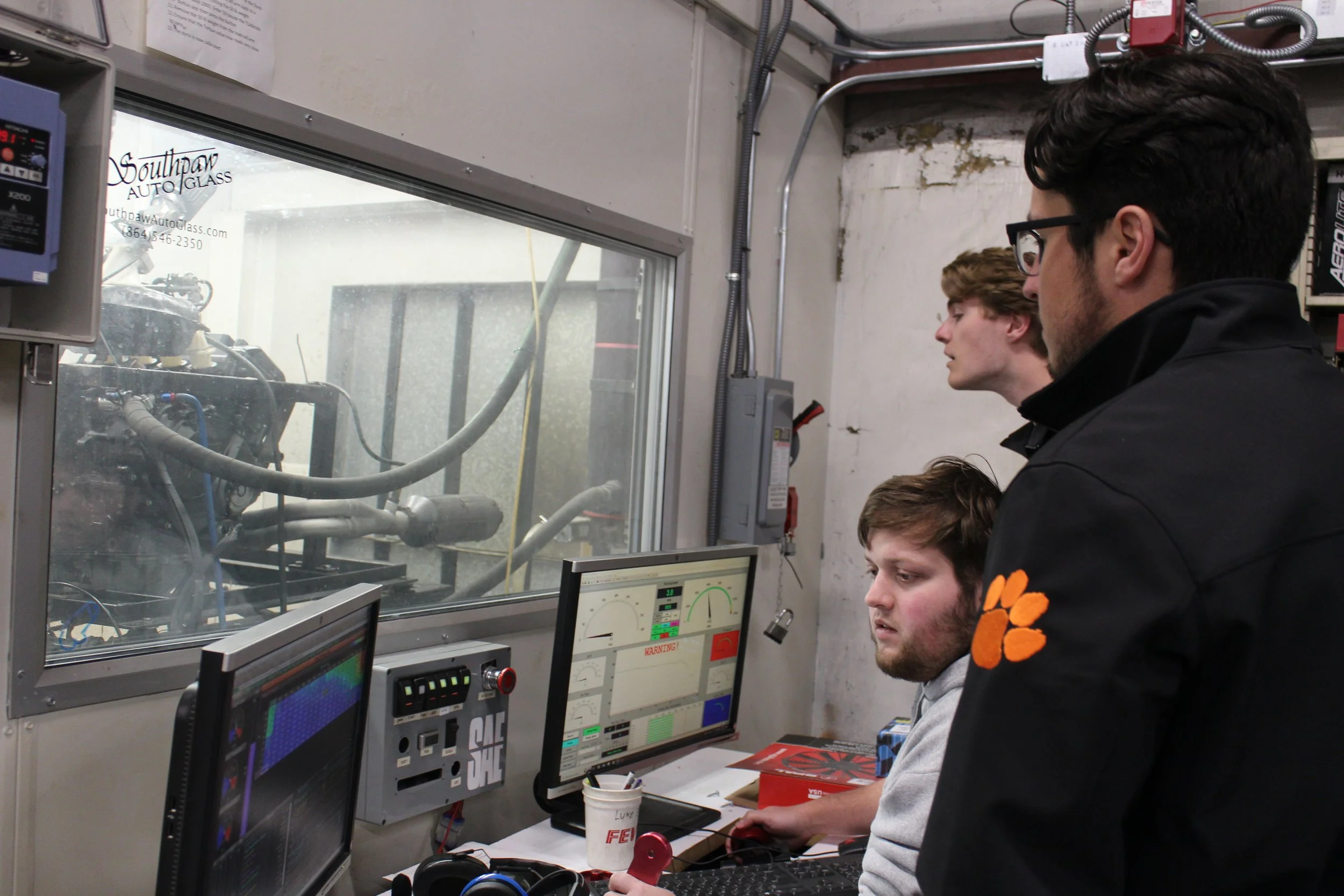

Powertrain division

The Powertrain division is responsible for the vehicle’s engine and all of the subsystems that harness the power it generates. Division members are involved with every part of the system, from engine tuning to cooling design. The Electrical and Powertrain divisions collaborate to maintain a working engine dyno that allows us to develop tuning packages and test the engine without the required overhead of running the full car.

Powertrain division members operating our in-house engine dyno.

Suspension division

The Suspension division is a combination of geometric suspension design and Vehicle Dynamics testing and tuning. This sub-team is responsible for how the car handles and controlling the interactions between the tires and the ground. From setting spring/damping rates and adjusting alignments to mathematically solving for wheel kinematics, the Suspension Division is a perfect fit for those who enjoy getting their hands dirty and making on the fly adjustments based on driver feedback to those who would rather perform simulations and create models on computers.

Suspension members inspect an outboard assembly on the Tiger 23 during a test day session.